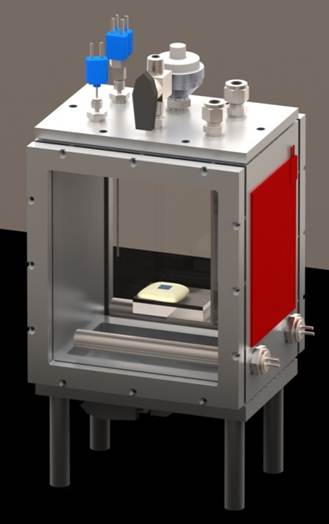

Pool Boiling Test Setup

Designed for a pool boiling testing over both high and low pressure and variable working fluids including water, ethanol, acetone, and etc. When used with high speed camera, this facility has the ability to acquire a precise analytical and visual data for analyzing boiling phenomena.

- Specifications:

- Internal Volume: 150x120x170 [mm³]

- External Volume: 180x150x230 [mm³]

- Two tempered glass view ports

- Two cartridge heaters for a rapid heating and degassing [400W each]

- Two band heaters for maintaining the temperature [200W each]

- External condenser with valve for degassing

- T-type thermocouples for measuring liquid and vapor temperature

- Pressure transducer for measuring the system pressure

- Drain valve for rapid liquid replacement

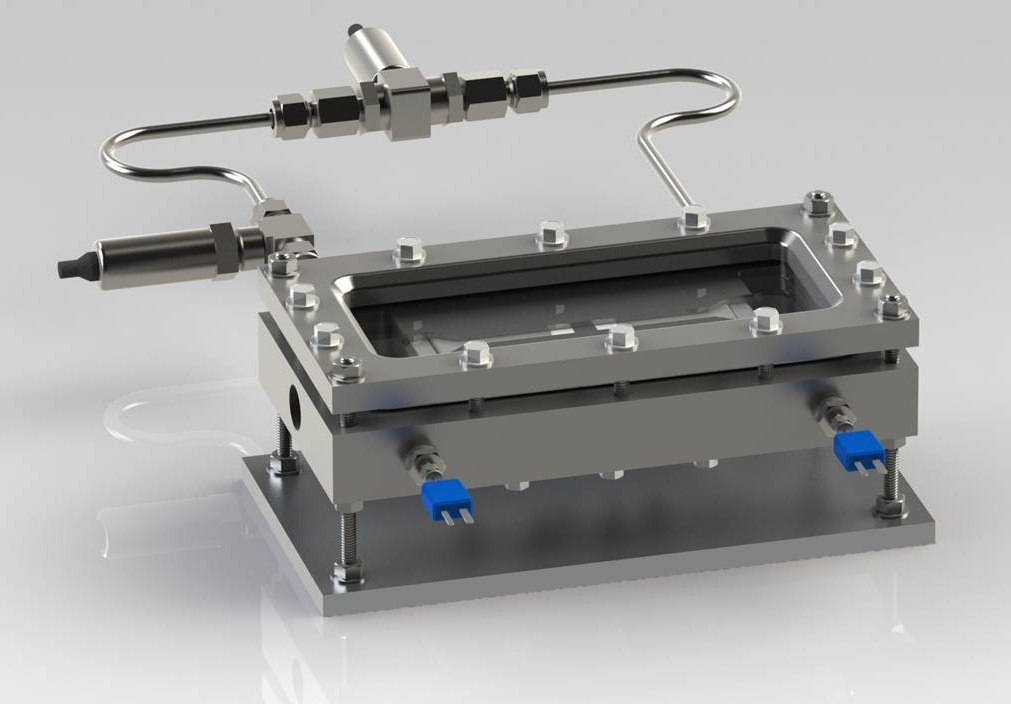

Flow Boiling Test Setup

- Test Rig for performing Flow Boiling

- low to moderate flow rates (xxx-xxx)

- saturated and subcooled flows

- high and low pressure,

- compatible with a wide range of fluids.

- High Speed Video Acquisition

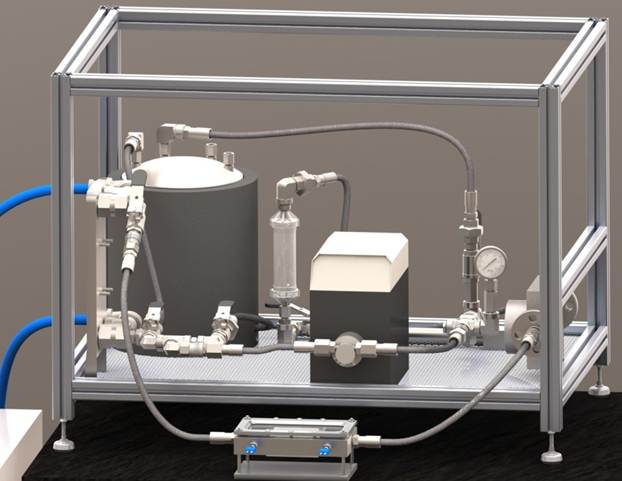

Spray Boiling Test Setup

Electrowetting On Dielectric (EWOD) Test Setup

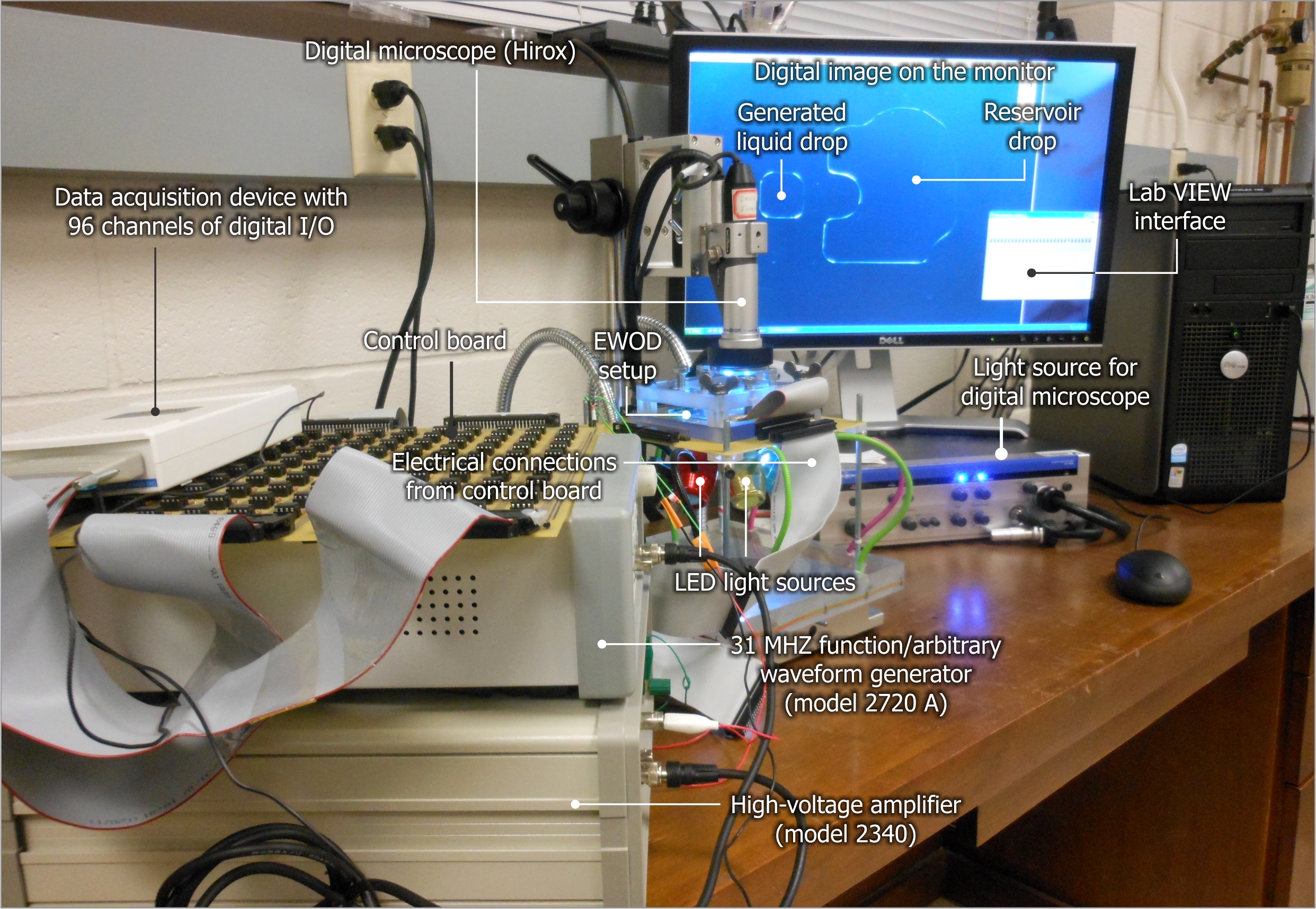

The EWOD system is mounted on a home-built fixture system which is made of transparent Lexan sheets. It provides a stable and strong rest for the EWOD setup without any bending deformation. Customized connecting pads with spring-loaded contact pins are used to provide electrical connections to the EWOD setup. This connecting pad is eventually connected to the external control board. Liquid drops in the EWOD setup are illuminated by the LED light sources placed below the EWOD setup. A sinusoidal signal (frequency 1 kHz) was generated from the waveform generator (Model 2720 A, Tegam) which is connected to the high-voltage amplifier (Model 2340, Tegam) to provide high enough AC voltage (~ 100 V) for testing. For the EWOD operation, a control signal (digital 1/0) was generated by the custom-built LabVIEW interface with a Data Acquisition Device (High-Density Industrial Digital I/O for USB – 96-Channel, 5 V TTL/CMOS, National Instrument Inc). This control signal is transformed into high voltage AC signal by the control board and supplied to the required electrode in the EWOD device. High speed drop dispensing and motion are recorded by the high speed camera and analyzed in Sine Viewer Application (CV 2.14b, Phantom, www.visionresearch.com). All the EWOD operations are tested in parallel plate EWOD device in air environment. Model liquid is Deionized water.

To learn more about the basics of EWOD, click here.

- In addition, the MSHT Lab is equiped with:

- Drop Shape Analysis System (Goniometer)

- 3-D Optical Microscope.

- Nitrogen & Vacuum Environment High Temperature Oven (~1600°C).

- Controlled Humidity and Temperature Test Chamber

- Multiple kW Power Supplies & Refrigerated Chillers

- Multiple Data Acquisition Systems.